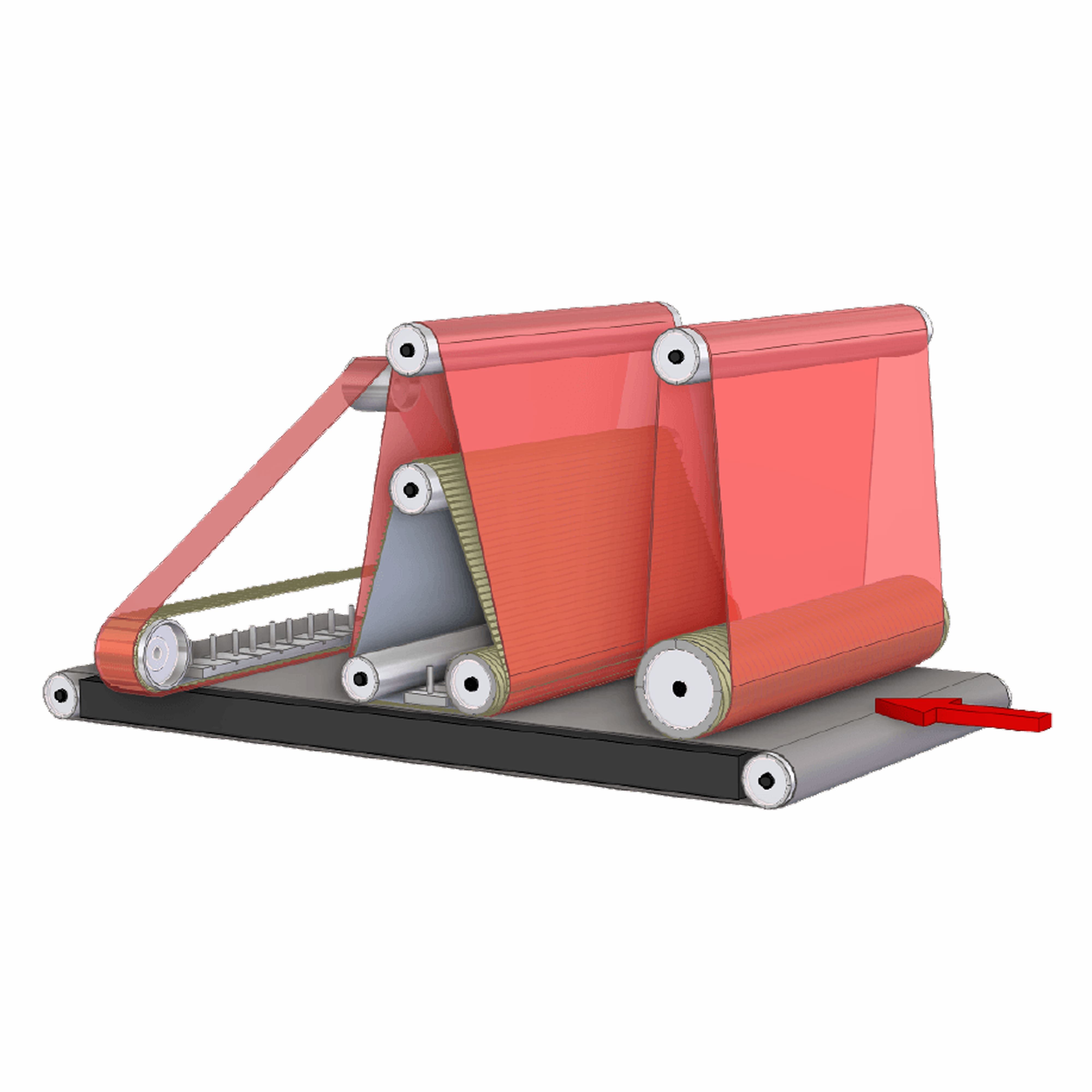

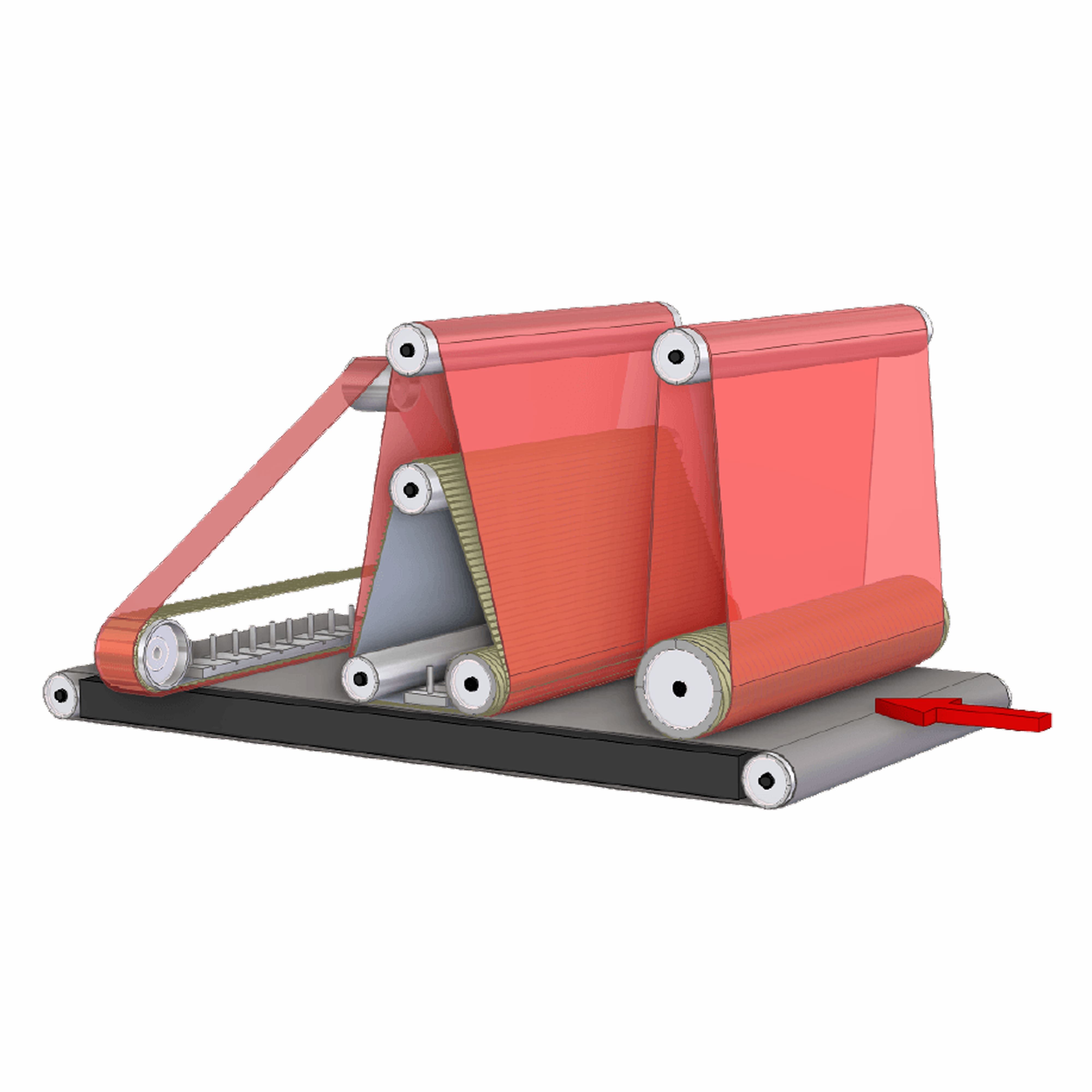

GRACIOUS 2725 C1

Sanding Machine with Cross Belt for Furniture

This high-tech sanding machine is specifically engineered for the furniture manufacturing and decorative veneer industries. It offers advanced sanding capabilities using a multi-head system that includes sanding/calibrator rollers, combi heads with segmented pads and chevron belts, and a cross belt system for across-the-grain sanding.

The electromagnetic segmented pad provides intelligent pressure control across the sanding surface. Each segment responds independently based on the surface contour, ensuring uniform pressure distribution, minimal material wastage, and a consistently smooth finish.

This level of precision is especially valuable for delicate decorative veneers and complex surface profiles. The machine’s flexible configuration allows for highly accurate sanding across different production stages, including pre- and post-sealing, and after PU or lacquer coatings.

Specific Features

- Dual Configuration options :

- Option 1: For pre-calibrated materials with a soft rubber roller on the first head, a combi head (with segmented pad and chevron belt) on the second, and a cross belt on the third

- Option 2: For non-calibrated materials with a steel hard chrome calibrator roller as the first head, followed by the same combi and cross belt setup

- Cross belt sanding system: Provides accurate across-the-grain sanding using segment pads and chevron belts

Application

- Primarily used in the processing of decorative veneers and wood surfaces in the furniture industry

- Supports critical applications such as across-the-grain sanding, straight-line veneer finishing, pre-sealing and post-sealing surface preparation, and fine sanding after PU coating or lacquering

- Dual-configuration makes it ideal for handling both calibrated and non-calibrated veneer sheets

Market Expectation

The market increasingly demands high-precision and versatile sanding solutions capable of handling complex veneer designs and multiple coating stages. The ability to sand pre- and post-sealed surfaces, including those with PU or lacquer coatings, is now a fundamental requirement

Our Solution

By offering two configuration options, it meets the needs of both calibrated and non-calibrated material processes. Its advanced sanding heads and flexible functionality ensure precise, consistent results across a wide range of surface types and coating stages—making it the ideal solution for manufacturers seeking efficiency, versatility, and uncompromising quality.

Technical Specifications

| Working Thickness | 2-100 mm |

| Working Width | 100-1250 mm |

| Number of Heads | Three |

| Head Configuration | R - RP - CB |

| Head 1 | Sanding with Rubber Roller; 25 HP (18.64 KW) |

| Head 2 | Soft Rubber Contact Roller and Segment Pad; 20 HP (15 KW) |

| Head 3 | Cross Belt Polishing with Segment Sanding Pad; 15 HP (11 KW) |

| Vacuum Blower | 5 HP (3.7 KW) |

| Sanding Belt Size | 2620 X 1330 mm & 4950 X 150 mm |

| Feeding Speed | 5-30 mpm |

| Feed Motor | 5 HP (3.7 KW) |

| Brush Motor | 1 HP (0.75 KW) |

| Vertical Motion Motor | 1 HP (0.75 KW) |

| Total Power | 72 HP (54 KW) |

| Weight | 4500 Kg |

| Dimensions | 2000 X 2250 X 2735 mm |