CONIFOROUS PS6

Profile Sanding Machine for Doors and Furniture

The Profile Sanding Machine is designed for sanding intricate groove areas and flat surfaces, making it ideal for profiled and CNC-routed doors. It ensures thorough sanding, including under-groove sections that conventional machines often miss.

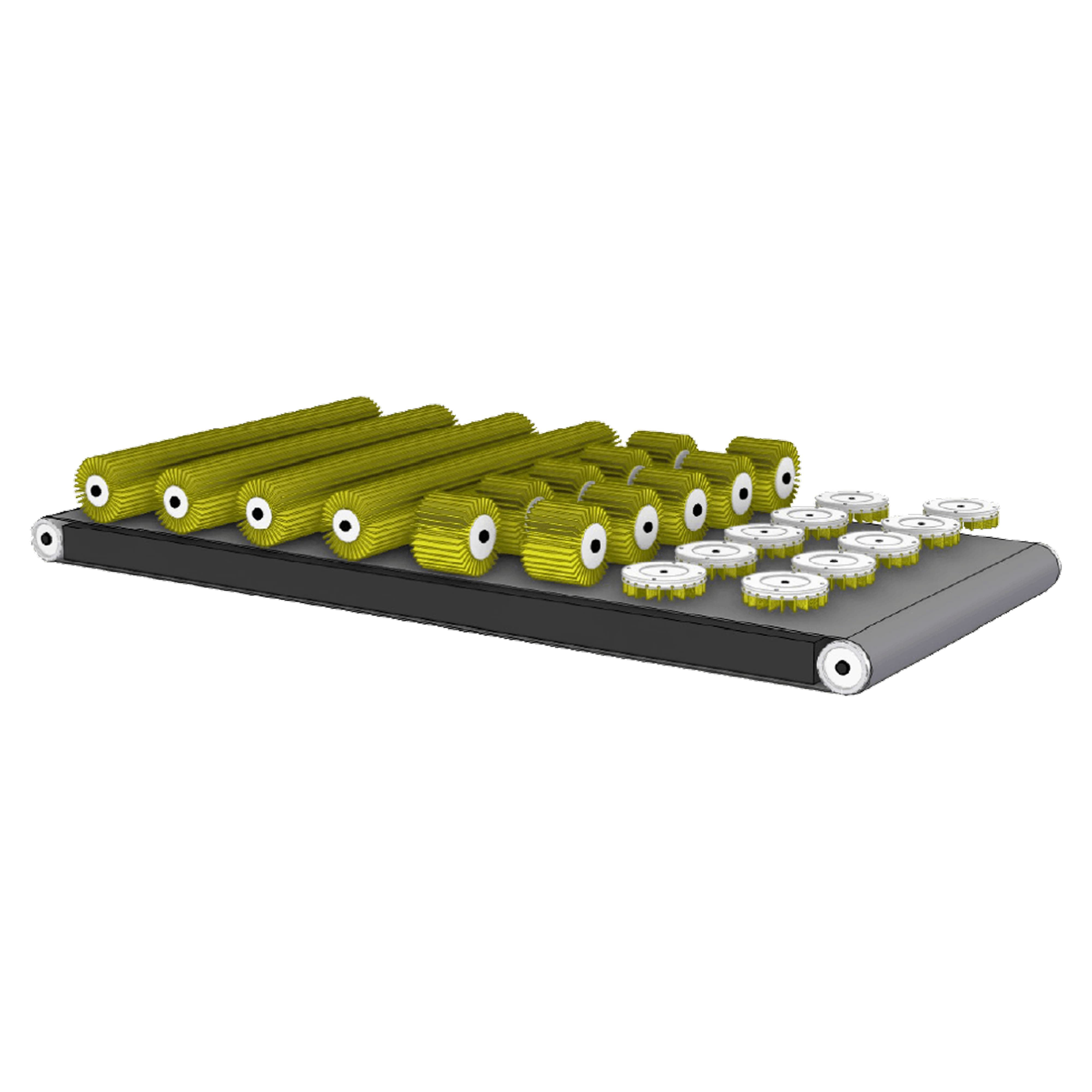

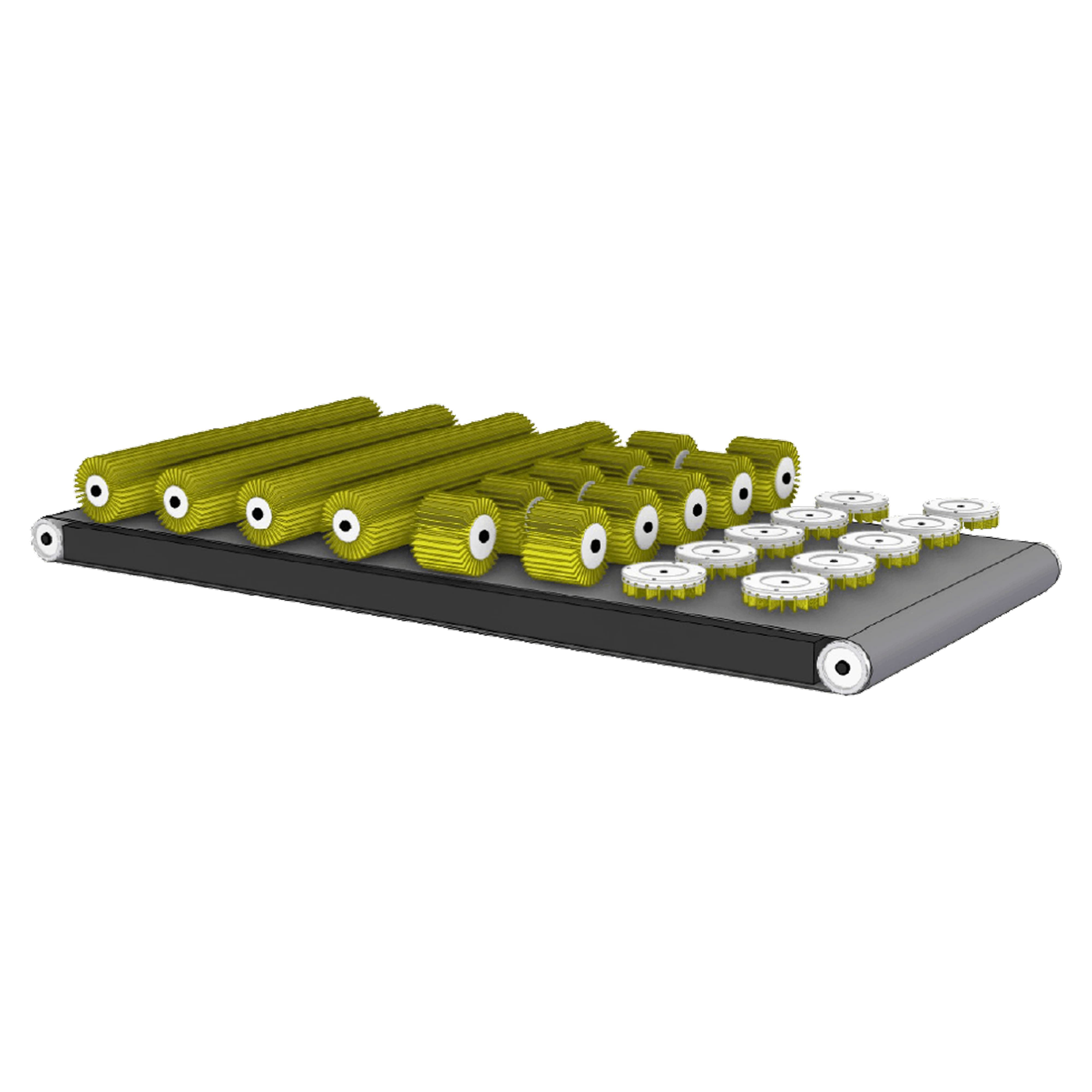

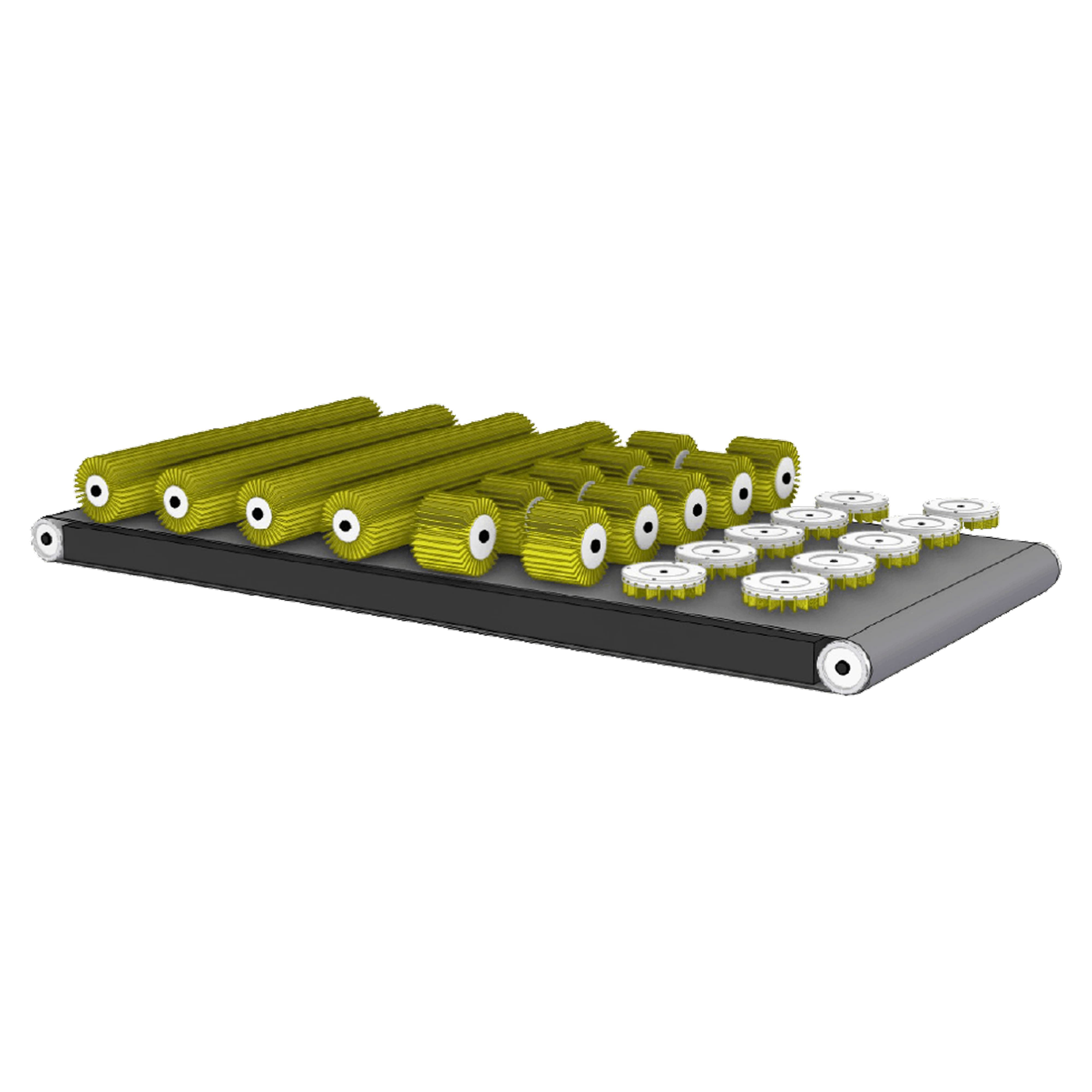

Equipped with 6 or 8 heads (depending on the model), the machine features a combination of disc rollers, full-size longitudinal rollers, and small longitudinal rollers. Each head offers both oscillating and rotational motion for complete surface coverage.

The mix of circular and longitudinal brush rollers in various grit grades allows precise sanding of complex profiles. This results in a smooth, consistent finish on both flat and detailed grooved areas—ideal for high-end door and panel production.

Specific Features

- Multiple sanding heads, including disc, full-length longitudinal, and small-width longitudinal rollers

- Oscillating and rotational motion for complete surface coverage

- Optimized for intricate groove areas and CNC-cut profiles

- Adjustable grit combinations for precise sanding on complex designs

- Robust construction for consistent, high-quality results on both flat and recessed areas

Application

- This machine is specifically designed for sanding grooved doors made from various wood types.

- It excels on doors and panels with intricate CNC-cut grooves, decorative patterns, and profiled surfaces.

- Its advanced sanding system ensures uniform finishing across both flat and recessed areas, making it ideal for solid wood, engineered wood, MDF, and veneered doors.

- Commonly used in the production of designer doors, premium furniture components, and custom interior panels, it is essential for manufacturers demanding high-quality surface finishes on both standard and complex profiles.

Market Expectation

Market expects this machine to deliver high-quality sanding results across all sizes and types of doors, including those with complex grooved designs. Manufacturers require a solution that handles diverse materials and door styles with speed, precision, and minimal manual input—demands this machine meets through its advanced multi-head configuration and precision sanding technology.

Our Solution

- It is designed to meet the demand for consistent and flawless finishing on both flat surfaces and intricately profiled areas.

- We developed this machine with a strong focus on delivering maximum productivity, ease of operation, and long-term reliability

- Its user-friendly design ensures smooth handling and minimal operator effort, making it ideal for both skilled and semi-skilled workers.

- It’s a complete package designed to perform, support, and deliver value in every aspect.

Technical Specifications

| Working Thickness | 3-120 mm |

| Working Width | 200-1250 mm |

| No. of Heads | Six |

| 1st Head | Brushing with Brush Roller; 2 HP (1.5 KW) |

| 1st Head Oscillation Motor | 1 HP (0.75 KW) |

| 2nd Head | Brushing with Brush Roller; 2 HP (1.5 KW) |

| 2nd Head Oscillation Motor | 1 HP (0.75 KW) |

| 3rd Head | Brushing with Brush Roller; 2 HP (1.5 KW) |

| 4th Head | Brushing with Brush Roller - 2 HP (1.5 KW) |

| 5th Head | Brushing with Brush Roller - 2 HP (1.5 KW) |

| 6th Head | Brushing with Brush Roller - 2 HP (1.5 KW) |

| Feeding Speed | 5-20 mpm |

| Feed Motor | 3 HP (2.2 KW) |

| Vertical Motion Motor | 1 HP (0.75 KW) |

| Total Power | 18 HP (13.5 KW) |

| Weight | 2900 Kg |

| Dimensions | 4200 X 2050 X 1900 mm |