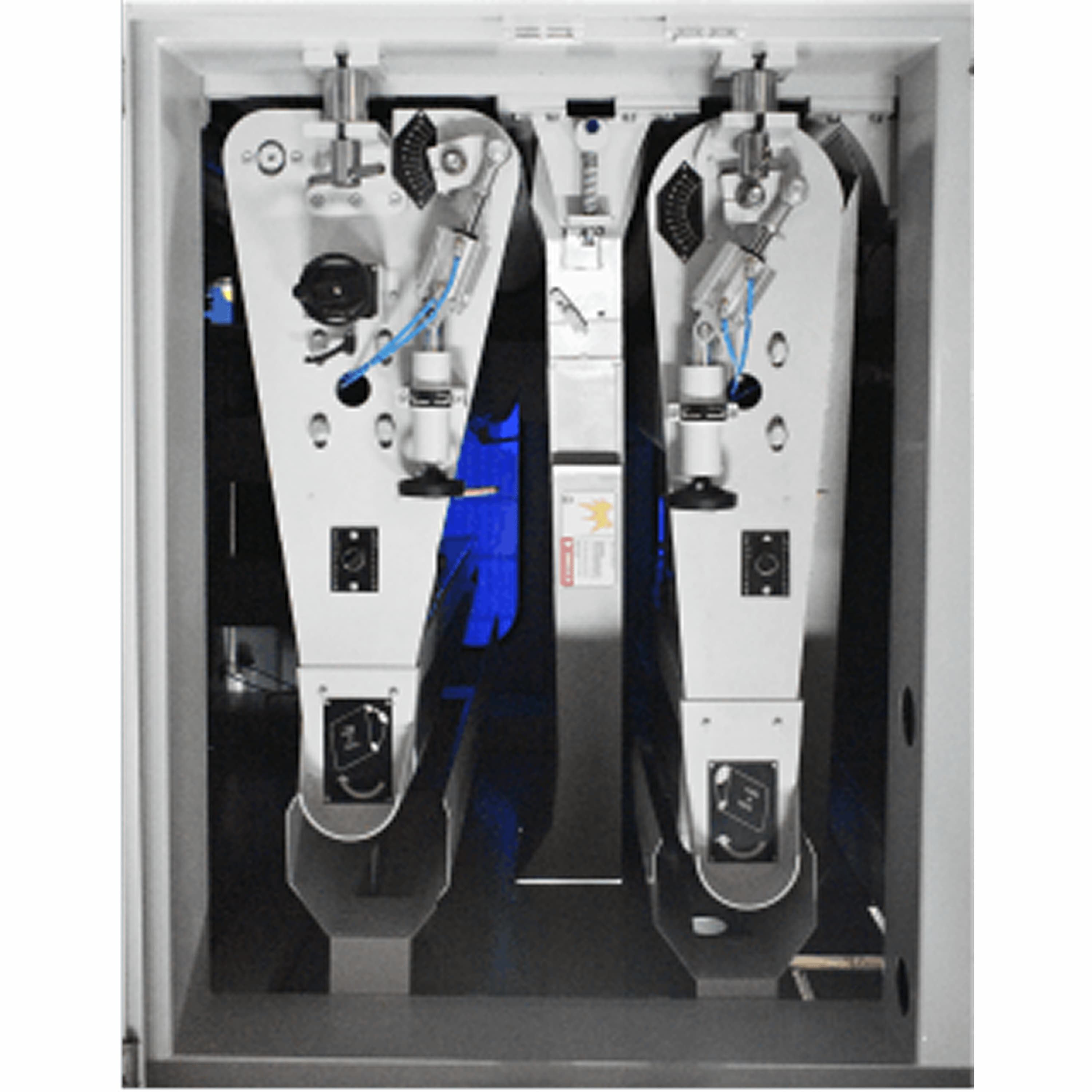

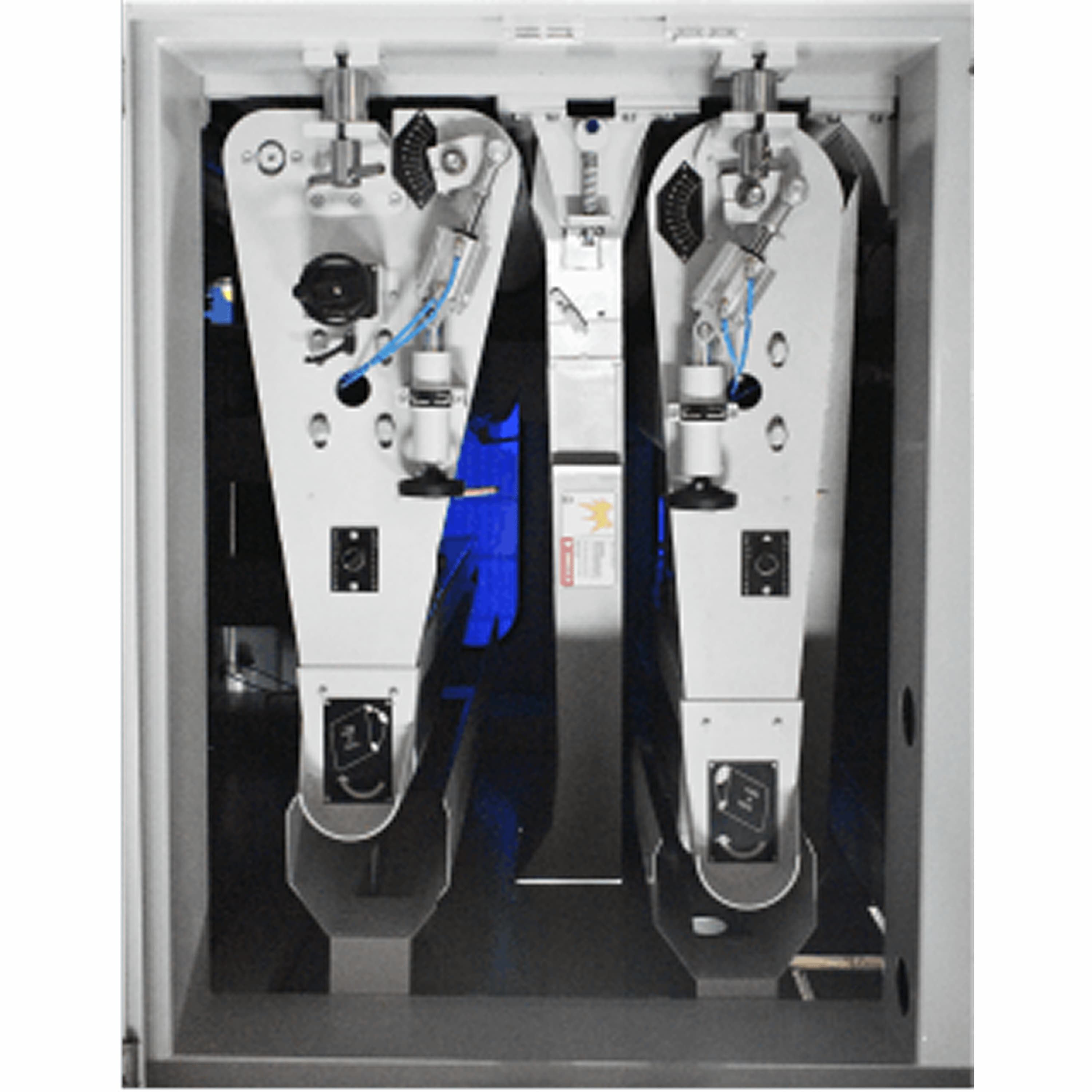

GRACIOUS 2725 B/2

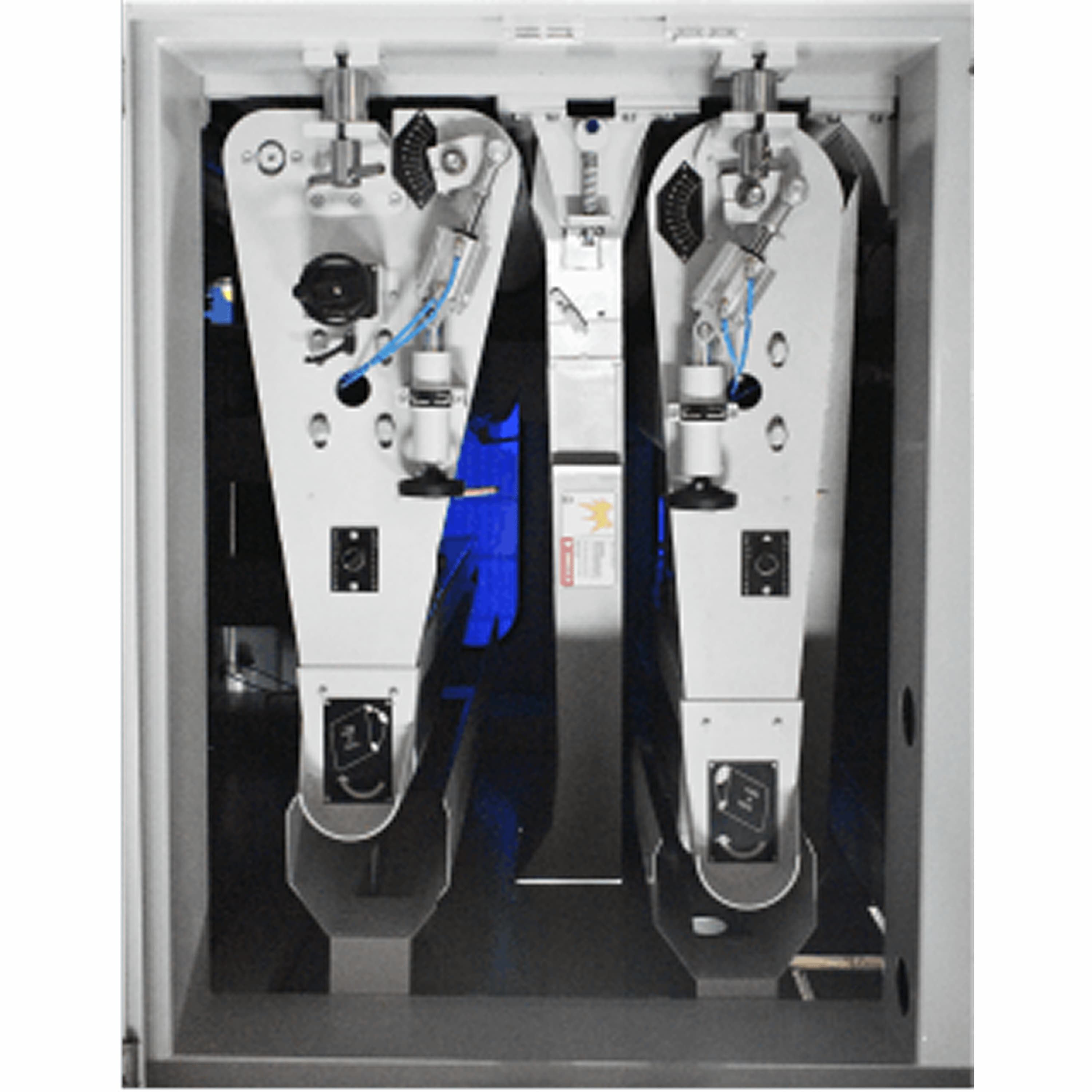

Double Head Wide Belt Sanding Machine - Bottom

The Wide Belt Bottom Sanding Machine was developed to meet the need for two-sided sanding without manual flipping, seamlessly pairing with the top sanding msachine. It features Servo-Controlled Floating Roller Technology for precise veneer protection, even with thickness variations.

The 1st Head offers super glossy sanding with high-tech, variable-speed rollers, while the 2nd Head acts as a support or sanding roller as needed. With specialized rubber, precise diameter, and advanced grooving, it delivers a flawless, glossy finish with full power failure protection.

Specific Features

- Used in synchronization with top sanding machine

- Perfect sanding results on uneven thickness

- Highly glossy sanding results, similar to top sanding machine

- Fast production, as both side sanding is achieved in one pass

- Built-in safety feature for both operator and machine

Application

- Manufacturing units producing plywood in all grades - commercial and decorative - across all thicknesses & sizes require this type of machine in addition to a Top Sanding Machine when production increases

- Production speed becomes double by adjoining with existing machine and there is no need of flipping the ply

Market Expectation

- Eliminate the need of flipping the ply for Sanding after top side finish

- Even sanding from all the corners without any sanding off

- Economical solution for high finishing and glossy touch on the surface of plywood and at the same time being user friendly

Our Solution

- Eliminating the need to flip the ply by using bottom sanding solution, hence saving time & labour cost

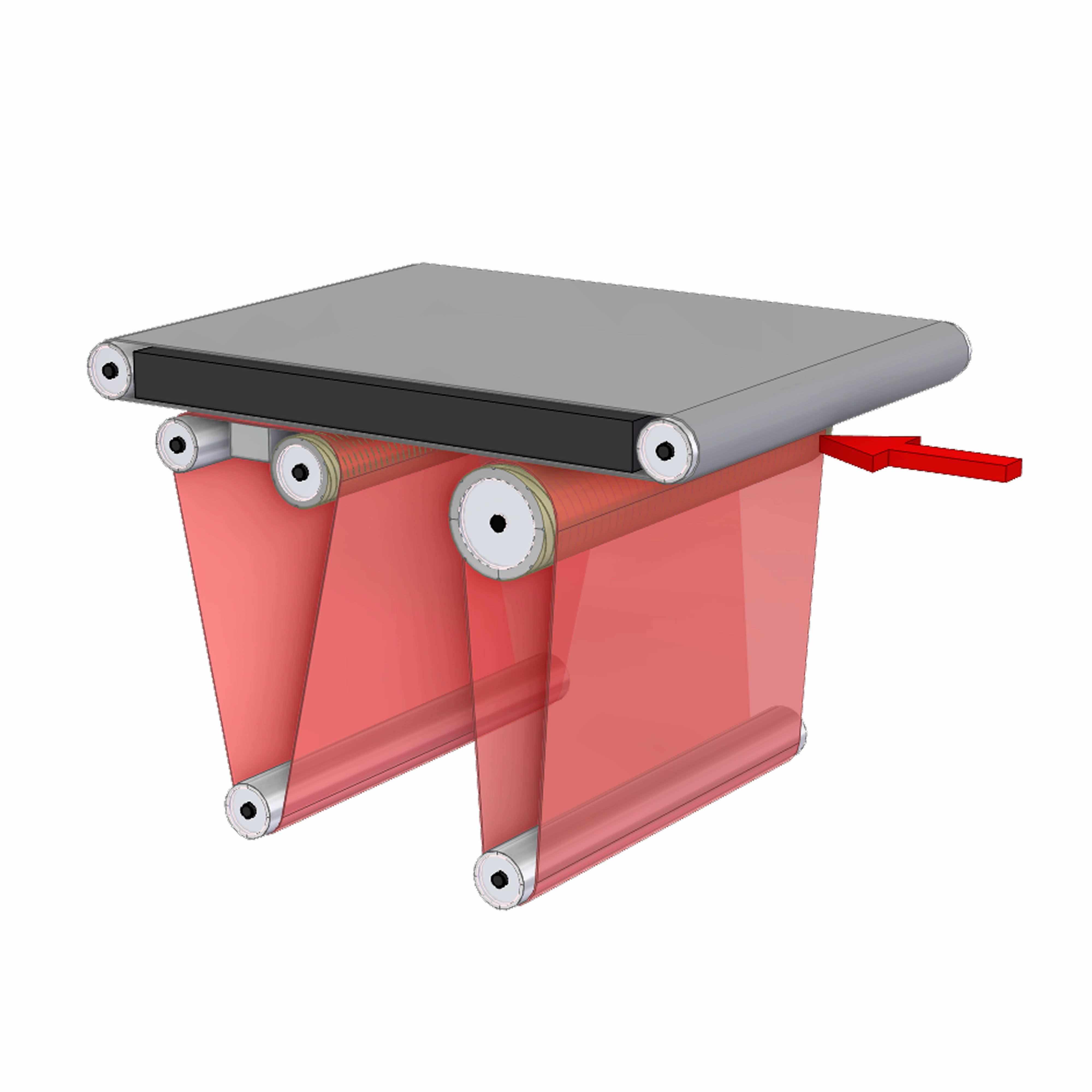

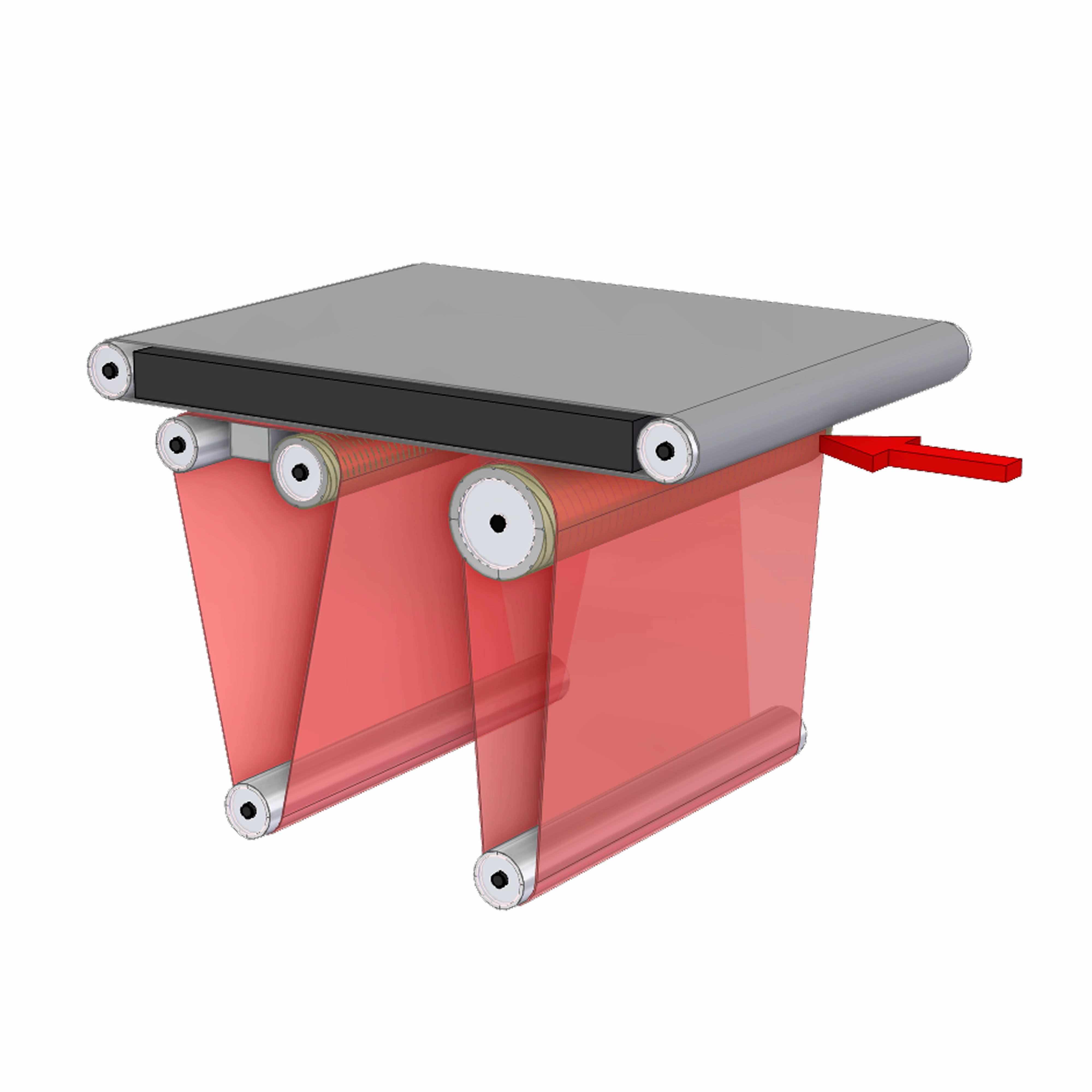

- Servo-Controlled Floating Roller Technology smartly protecting face veneer even with thickness variations

- Sanding unit with a combi head unit works in a way which gives a glazing effect on the surface of plywood

- Highest working efficiency, saving considerable energy

Technical Specifications

| Working Thickness | 2-100 mm |

| Working Width | 200-1250 mm |

| Number of Heads | Two |

| Head Configuration | R-R/P |

| Bootom - Head 1 | Sanding with Rubber Roller; 25 HP (18.64 KW) |

| Bottom - Head 2 | Polishing with Sanding Pad; 20 HP (15 KW) |

| Sanding Belt Size | 2620 X 1350 mm |

| Feeding Speed | 5-40 mpm |

| Feed Motor | 5 HP (3.7 KW) |

| Vacuum Blower Motor | 5 HP (3.7 KW) |

| Vertical Motion Motor | 2 HP (1.5 KW) |

| Total Power | 57 HP (42.5 KW) |

| Weight | 4200 Kg |

| Dimensions | 2250 X 2100 X 2600 mm |

Info copied to clipboard