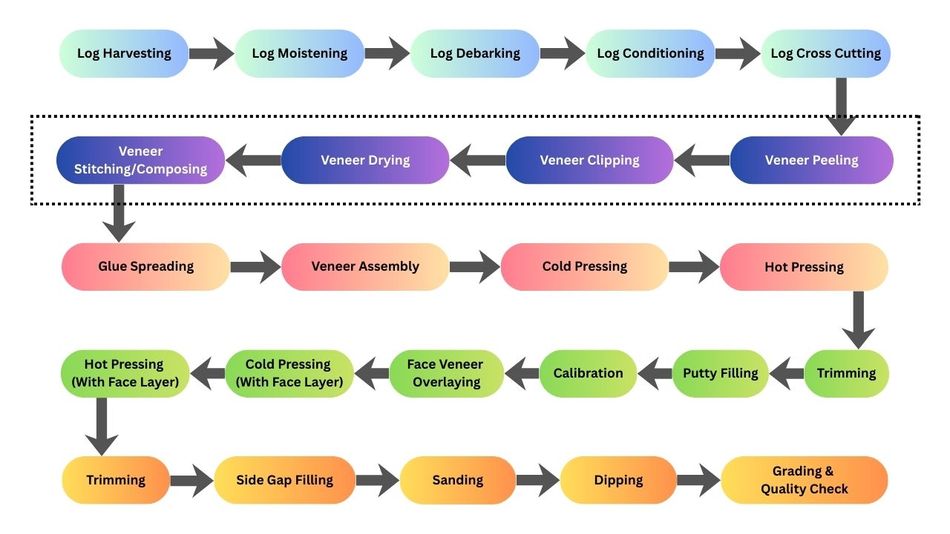

How is Plywood made : The Full Process Explained | Part-2

In this stage of plywood manufacturing, raw logs are processed into uniform, high-quality veneers that form the essential structural foundation for strong, durable, and dimensionally stable plywood.

This is the second article of this blog series. To read the first article, please refer this link.

In the first part of this series, we discussed how a wooden log is conditioned and prepared. In this second part, we will move deeper into the production line and explore the next set of critical operations, including:

- Veneer Peeling

- Veneer Clipping

- Veneer Drying

- Veneer Stitching/Composing

Veneer Peeling

The cross-cut wooden log is fed into a peeling machine (or slicer), which converts the log into thin sheets known as veneers. These veneers serve as the fundamental building blocks of plywood.

In a peeling machine such as a Rotary Peeling Lathe, the log is rotated at high RPM against a stationary knife blade. With precise pressure and alignment, the blade continuously peels off a long, ribbon-like sheet of wood—much like unrolling a roll of paper. These long sheets are later clipped to standard size and used to assemble plywood.

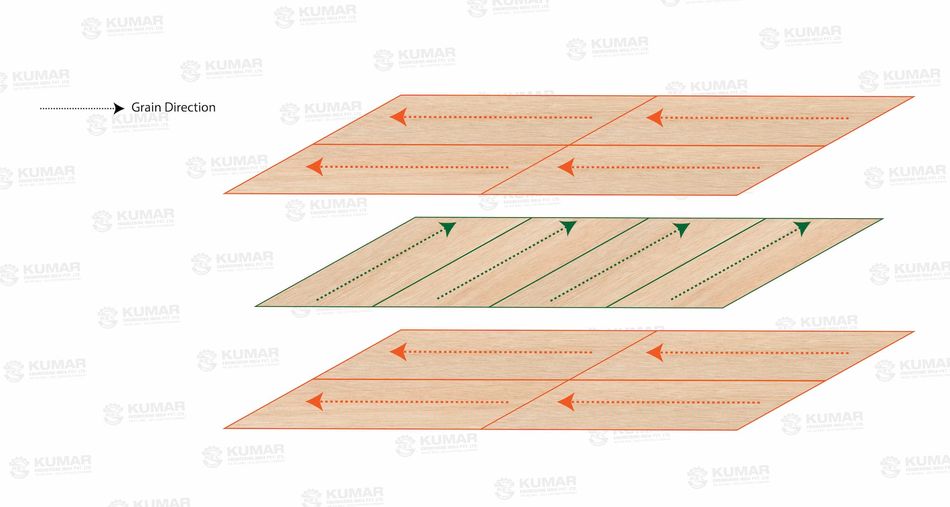

A plywood panel is created by stacking multiple veneer layers in alternating grain directions to achieve strength, stability, and thickness.

There are three primary types of veneers used in plywood manufacturing:

-

Face Veneer

- The topmost, visible surface layer of plywood.

- Selected for appearance, smoothness, and grade quality.

-

Core Veneer

- The inner structural layers.

- Contributes to the thickness, strength, and load-bearing capacity of the plywood.

-

Panel (Cross-Band) Veneer

- Intermediate layers placed between face and core veneers.

- Slightly thinner than core veneers and arranged perpendicular to adjacent layers grain direction to enhance dimensional stability.

Comparison of Veneer Types

| Veneer Types | How they are obtained | Thickness Range |

|---|---|---|

| Face Veneer |

|

|

| Core Veneer | Rotary Peeling | 1.5mm to 3.5mm |

| Panel (Cross-Band) Veneer | Rotary Peeling | 1mm to 2mm |

Among all veneer types, Core Veneers are the thickest, followed by Panel Veneers, and finally Face Veneers, which are the thinnest—especially when produced through slicing.

Veneer Clipping

Once the veneer sheets are obtained after peeling or slicing, they are not immediately ready for drying or assembly. Rotary-peeled veneers often come out as long, ribbon-like sheets, but in practice, these ribbons are sometimes non-continuous. Natural log taper, knots, cracks, and occasional issues such as inadequate knife pressure cause the sheet to break at intervals.

Sliced veneers, on the other hand, are produced by sliding a stationary knife across a wood block. While slicing generally produces more uniform sheets, they are also generated in long strips that must be cut to workable sizes.

To convert these irregular, long sheets into standard and manageable pieces, the veneers are passed through a veneer clipping machine. The clipper trims the sheets into consistent dimensions — most commonly 4 ft × 4 ft or 4 ft × 2 ft or 4ft x 8ft, but with an extra margin for trimming in later stages.

Also note that due to natural defects and irregularities in the veneer sheet—as mentioned earlier—certain portions must be removed. As a result, the remaining veneer pieces may not always be standard sizes. Instead of 4 ft × 8 ft, we may obtain intermediate sizes such as 4 ft × 3 ft or 4 ft × 1 ft, depending on how much defective area was removed.

Veneer Drying

Freshly peeled veneers contain a high amount of moisture. This moisture comes not only from the wood’s natural internal water but also from earlier stages such as Log Moistening and Log Conditioning, where logs are soaked or steamed. As a result, the moisture content(MC) of a freshly peeled veneer is usually well above 30%, and often much higher.

However, veneers with such high moisture cannot bond properly during gluing. Excess moisture prevents the adhesive from penetrating the wood fibers and weakens the bond strength.

At the same time, the moisture cannot be removed completely. If veneers are over-dried—brought close to 0% MC—they become brittle, develop cracks, warp, and lose flexibility, making them unsuitable for handling and layup.

Formula of the Moisture Content :

(Weight of Water in Wood / Over-dry weight of the wood) * 100

Therefore, the moisture content must be precisely controlled. Veneers are dried to an optimal range of 4% to 10% MC, depending on the type of plywood being manufactured. Maintaining this targeted moisture range is one of the most critical factors in producing high-quality plywood.

Drying Parameters

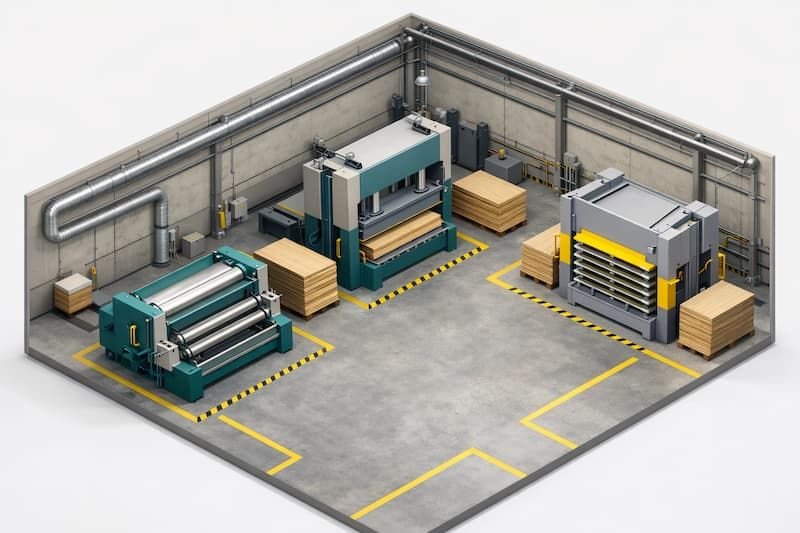

For drying the veneers, large industrial veneer dryers are used—typically jet dryers, roller dryers, or mesh dryers. Inside these dryers, precisely controlled high temperatures, regulated airflow, and uniform heat distribution work together to bring the moisture content down to the ideal range.

The drying time depends on several factors such as veneer thickness, wood species, initial moisture content, and dryer type.

- Thin face veneers : 1–2 minutes

- Panel/cross-band veneers : 2–4 minutes

- Thicker core veneers : 4–7 minutes

After drying, veneers are kept aside for about 24 hours for conditioning. This resting period allows the veneer to cool down, equalize its internal moisture, and regain flexibility. It helps stabilize the sheet, prevents cracking during handling, and ensures proper glue absorption in later stages.

Veneer Stitching/Composing

A plywood sheet is ultimately formed by stacking multiple layers of veneers—each layer placed at a 90° angle to the previous one (a detailed explanation of stacking is covered later in this series).

Suppose each veneer coming from the clipping machine is of size 4 ft × 2 ft. To create a standard 4 ft × 8 ft plywood panel, four such veneers must be placed side-by-side in a row. The next layer on top will again cover the full 4 ft × 8 ft area, but its grains will run perpendicular to the grains of the layer below, ensuring strength and dimensional stability.

However, if this assembly is done manually, placing narrow veneers next to each other often leads to small gaps between the sheets. Even slight gaps compromise the mechanical strength of the plywood, create weak spots, reduce bonding quality, and can even allow insect intrusion over time. Gaps also cause uneven pressure during hot pressing.

Therefore, veneers must be joined edge-to-edge with precision before they are assembled into plywood layers. This is where veneer stitching (or composing) machines come in. These machines stitch multiple veneer pieces together, ensuring that the joints are tight, gap-free, and consistent throughout.

Another important reason for using composing machines is the inconsistency in veneer sizes obtained during the Veneer Clipping stage. Due to defects or irregular sheet breaks, veneers may come in non-standard dimensions such as 4 ft × 5 ft, 4 ft × 3 ft, or even 4 ft × 1 ft. These pieces cannot be wasted and must be efficiently utilized.

Composing allows these smaller veneers to be stitched together into a larger, usable sheet, which is then trimmed to the standard 4 ft × 8 ft size required for plywood manufacturing.

Different types of veneers require different composing (stitching) machines, because each veneer category has its own thickness, flexibility, and end-use requirements. Accordingly, the stitching method, machine design, and stitching pattern vary.

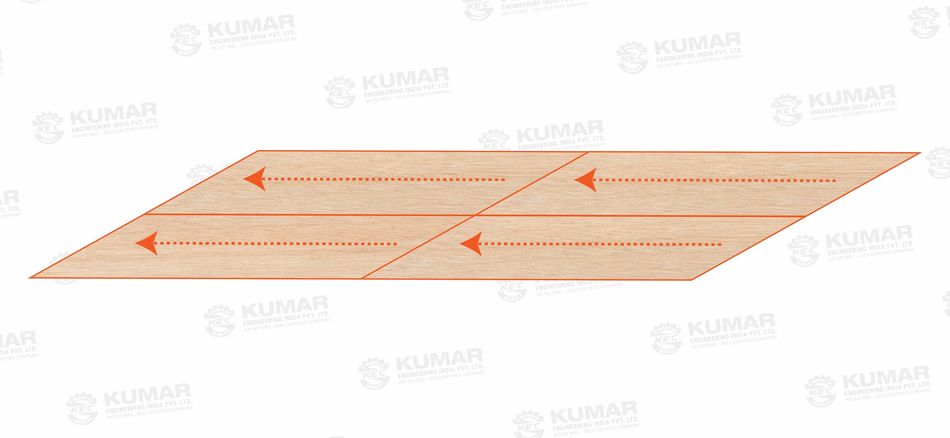

Core Veneers

A Core Composer Machine is used, where stitching is done using a heated polyester thread (often called hot-melt thread).

The thread melts into the veneer surface and bonds firmly, creating a robust joint. If 4ft X 2ft veneers are used, then these veneers are composed in a layout similar to a 1-row × 4-column matrix, forming a full 4 ft × 8 ft sheet from smaller clipped pieces.

Do checkout the tech specs of Core Composer Machine on this link.

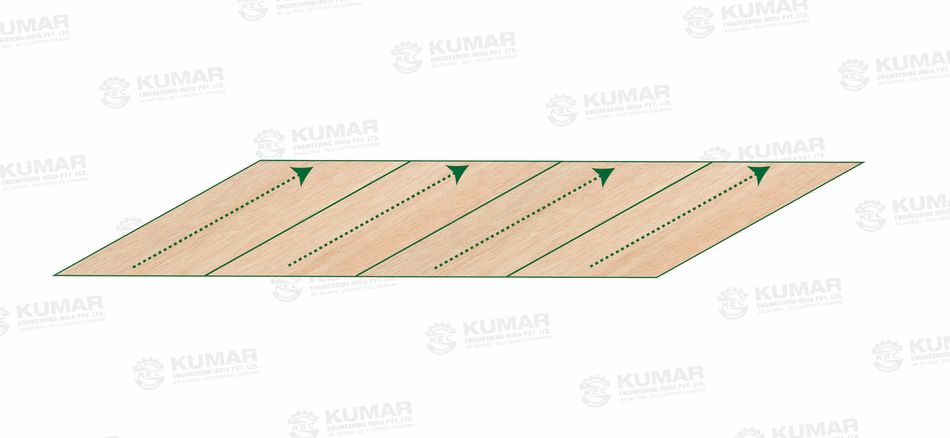

Panel Veneers

An L-Type Panel Composer Machine is used, which presses veneers from two sides while stitching or gluing the edges together.

Assuming 4ft X 2ft veneers are used, then these veneers are arranged in a 2-row × 2-column matrix to form a 4ft X 8ft sheet, ensuring uniformity and correct grain alignment across the full sheet dimension.

Face Veneers

A Veneer Splicing Machine is used for this purpose. The machine precisely trims and edges the veneers before joining them.

Face veneers are generally composed in a 1-row × 4-column matrix, if 4ft X 2ft veneers are used, forming a long, continuous, seamless surface of size 4ft X 8ft required for the outer face of plywood or laminates.

The stitching is fine, almost invisible, ensuring a flawless appearance after pressing and finishing.

Conclusion

In this article, we covered the journey of veneers from peeling to drying and stitching.

In the next part of this series, we will explore the remaining processes that turn these veneers into strong, durable plywood.

Read More Blogs

How is Plywood made : The Full Process Explained | Part-3

Learn how plywood is made through glue spreading, veneer assembly, cold pressing, and hot pressing. This detailed guide explains grain orientation, adhesive types, and pressing techniques that give plywood its strength, stability, and durability—essential knowledge for understanding modern plywood manufacturing.

10 January 2026

How is Plywood made : The Full Process Explained | Part-4

This article explains the post–hot press stages of plywood manufacturing, including trimming, putty filling etc. It highlights how these processes ensure dimensional accuracy, surface smoothness, and strong bonding for high-quality plywood production.

10 January 2026

How is Plywood made : The Full Process Explained | Part-5

Discover the complete plywood manufacturing process in this final part of our series. Learn how trimming, gap filling, sanding, chemical dipping, and quality grading transform raw panels into durable, market-ready plywood sheets built for strength, precision, and long-term performance.

10 January 2026